whitepapers

CINERGIA’s solutions for electromobility

CINERGIA has thorough experience in providing solutions for R&D, Functional and End of Line test in this field

Electromobility Platform

Mobility is one of the main challenges of the 21st century. Environmental concerns are driving a growing demand for more efficient and cleaner means of transportation. Advances in the field of electromobility are mainly linked to the development of battery technology and power electronics for charging, discharging and driving electrical motors.

Our knowledge and experience is your best partner in e-mobility test platforms.

CINERGIA has thorough experience in providing solutions for R&D, Functional and End of Line tests in this field. Our products have been improved from the experience gained by applying our technology to many e-mobility projects and working closely with our customers. This technical note describes the functions and characteristics of the main devices involved in the EV-Charging process and the testing solutions that CINERGIA can propose.

Off-board EV Charger

Test platforms

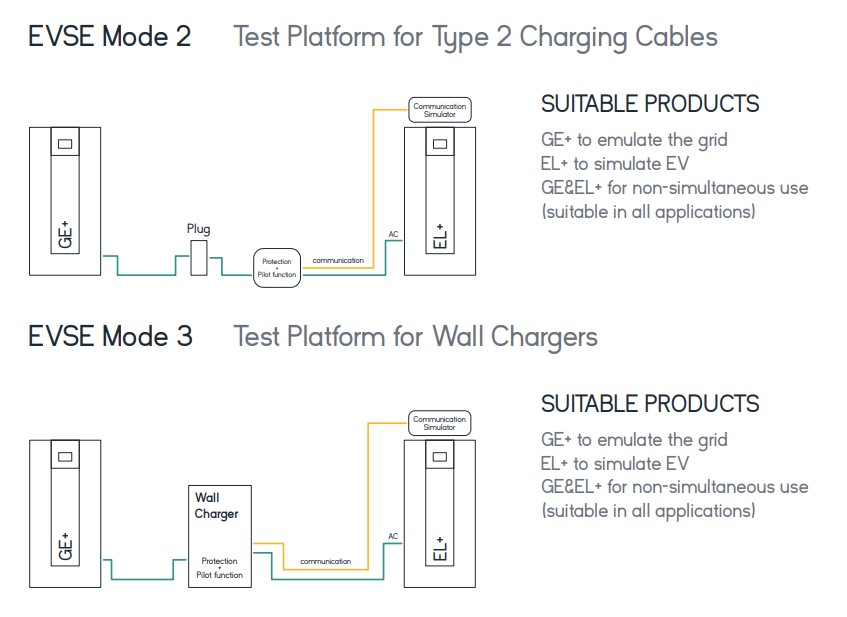

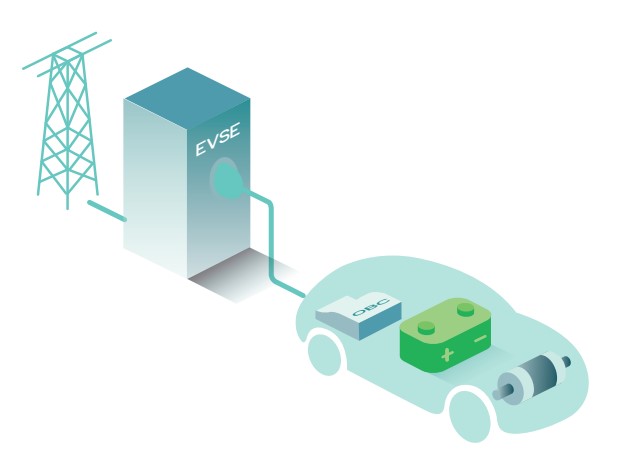

Electrical Vehicle Supply Equipment (EVSE), also called Off-board chargers, are the components interfacing the public grid to an electric vehicle. They are standardized in 4 different modes, described on the following page, depending on the power, safety functionality and communication capabilities.

EVSE manufacturers need to test their units from the AC grid side and the EV output side. Our Grid Simulator(GE+) can be used to provide stable and clean voltages, as well as to generate worldwide grids. When needed, the Grid Simulator will create disturbances following IEC 61000-4/11/13/14/28 standards. Our Regenerative Electronic Load will emulate the electrical behaviour of an EV both in AC (EL+) and in DC (B2C+) to test the output of a charger or a mode 2 cable. When simultaneity is not required, the combined All-in-one product (AC/DC, GE/EL) will offer the most cost-effective solution.

What charging modes exist?

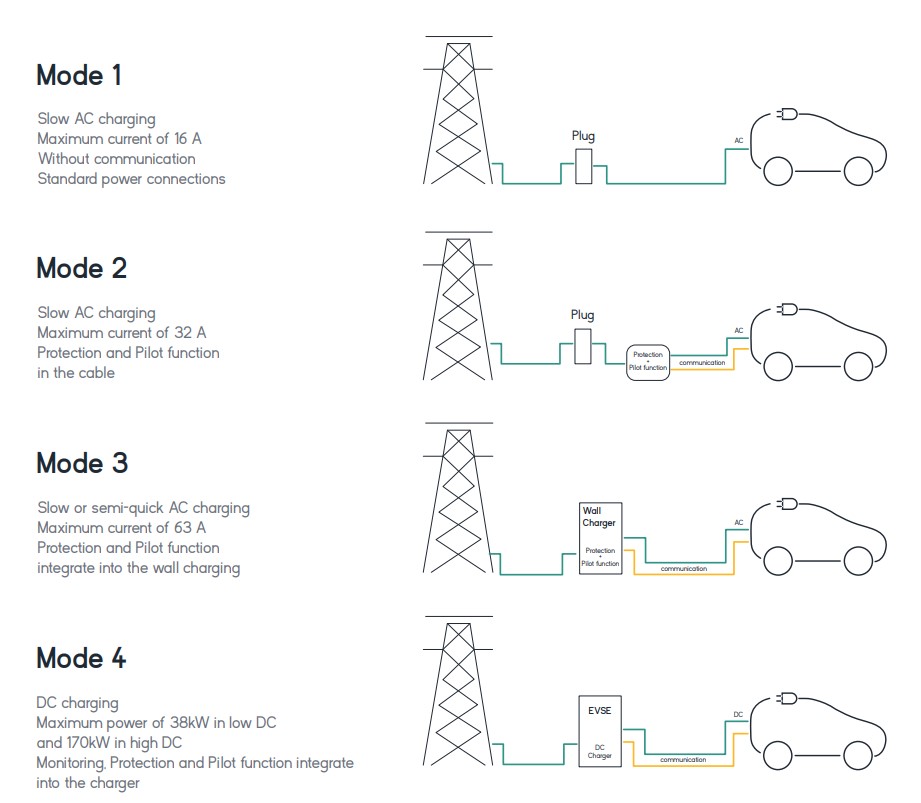

The charging process of the electric vehicle has been regulated by IEC-61851, where four charging modes are defined.

Mode 1: Slow charge in AC. From a conventional, standard plug base. There is no pilot function between the vehicle and the charging point.

Mode 2: Slow charge in AC. The cable includes communications, a ground monitoring system for safety and a pilot function.

Mode 3: Semi-fast charging in AC. Fixed charging point integrating communications, a ground monitoring system for safety and a pilot function.

Mode 4: Fast charging in DC. The charging point comprises an AC / DC converter, ground monitoring protection and communications integrated into the charger.

Our Solutions for

On-board Charger

Test platforms

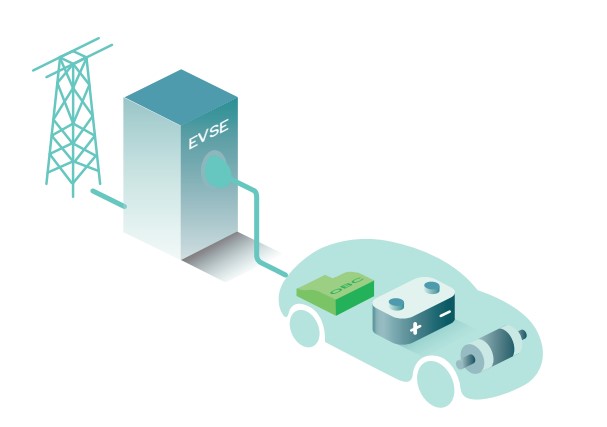

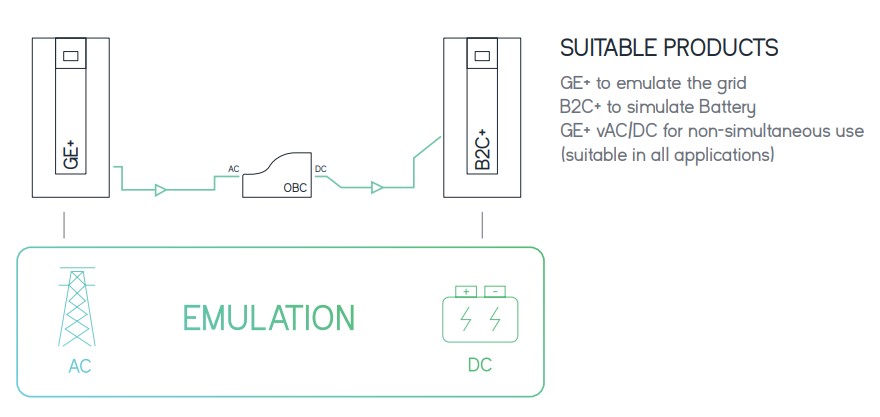

This AC to DC converters are used to charge the battery, in DC, directly from the public grid. They are embedded in the car, so they need to be light and in consequence, they are typically low-power AC to DC converters. In some cases, however, the charger is part of the drive train converter allowing high-power charging.

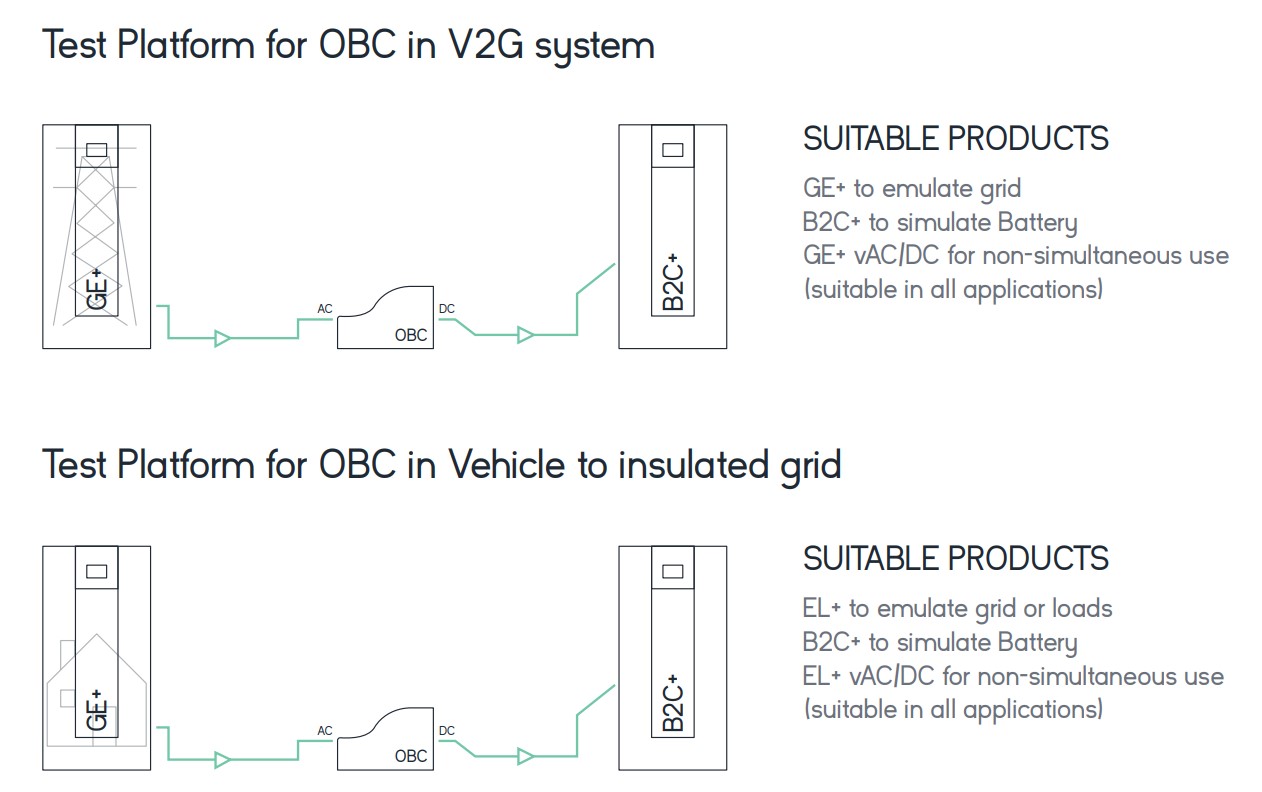

Our Grid Simulator (GE+) is perfect to test the AC side of the charger in stable and distorted conditions and perform functional and immunity assessments. The DC side will be tested using our DC Electronic Loads (B2C+) which include a software option to emulate the electrical behaviour of a battery.

Our devices can reduce the total power used thanks to his regenerative hardware. A flexible option to perform all kind of tests.

Our Solutions

Test platform for OBC charger

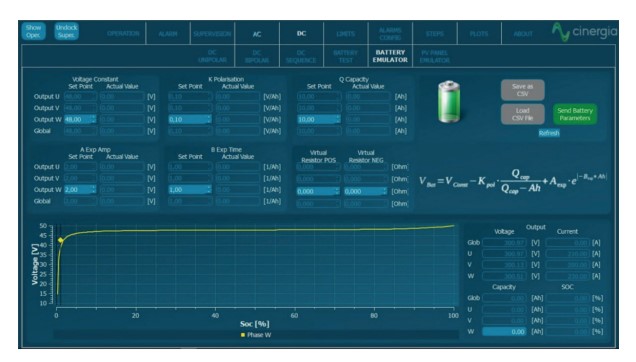

Battery Emulation

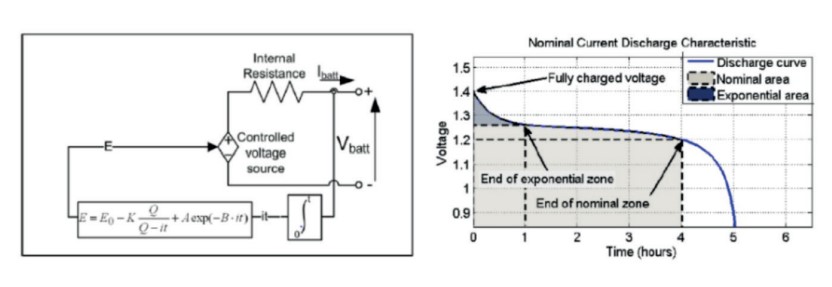

Battery Emulation. The B2C+ integrates a mathematical model to emulate the voltage behaviour of a real battery pack. The output voltage will change as a function of the SOC and Current. By configuring the provided parameters, the voltage profile can be adjusted to match different technologies: LiIon, NiMH, NiCd, Pb, Flux, etc.

Our battery emulation software works with a model from O. Tremblay, L.-A. Dessaint, A.-I. Dekkiche, “A Generic Battery Model for the Dynamic Simulation of Hybrid Electric Vehicles”, 2007 IEEE® Vehicle Power and Propulsion Conference, September 9-13, 2007, Arlington/Texas, USA.

Vehicle to grid (V2G) and Vehicle to home (V2H)

Test platforms

Vehicle-to-grid and Vehicle to home solutions are next-generation systems envisioned to convert the electric vehicle into an active agent of the electrical grid. These systems are able to reduce power consumption (becoming a controllable load) or supply energy from the EV battery into the grid to provide ancillary services in high-demand scenarios. New revolutionary developments go even further in using the EV battery as the energy resource of an islanded grid.

Battery

Test platforms

The constant research in this field has allowed to improve the performance in terms of autonomy, density and power ratings, among others. A key factor in this process is testing the new developments for the verification and characterization of batteries.

B2C+ (DC Bidirectional Converter) is CINERGIA’s model specially designed to test battery packs. Through our software, advanced tests can be configured and automated for charging, discharging, cycling, ageing and characterizing. Driving profiles can be emulated by downloading csv files.

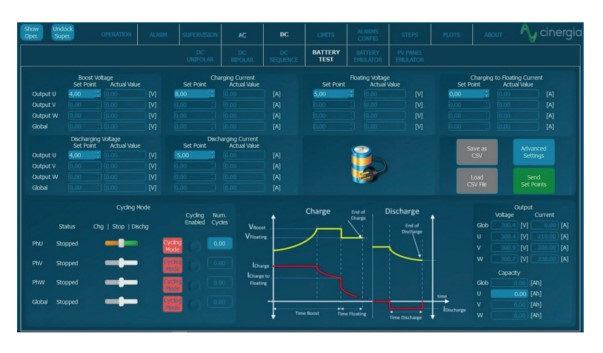

Battery Pack Testing

Battery pack testing. This functionality enables the user to precisely control the charge, discharge and cycling of a Battery. Basic parameters include the charge/discharge current, fast charge and floating voltages while Advanced parameters add Energy (Ah) and Time as transition conditions. Profiles for each Battery technology can be saved and imported in .CSV files.

EV Drive train emulation

Sequence. The User Interface Software integrates a Sequence Editor to create automatic test sequences, save them for future use and import them in .csv files. A smart datalogger can be activated to record automatically the resulting voltage and current measurements with a time resolution of 400 ms.

Sie können den gesamten Fall hier herunterladen

HERUNTERLADENWeitere Artikel

whitepapers

Enabling Zero-Emission Flight: Cinergia Powering the Future of Electric Aviation

Cinergia Power Solutions played a critical role in Dovetail Electric Aviation’s public demonstration of their hydrogen-hybrid electric propulsion system. Learn how our B2C+ regenerative power supply helped integrate and validate the entire drivetrain with precision and safety.

whitepapers

How to reap the benefits of Smart EV Charging safely and efficiently

Exploring the benefits and challenges of effective Smart EV Charging system deployment

whitepapers

Redefining End-of-Line Testing: Efficiency and Precision with Cinergia Solutions

Discover how Cinergia Power Solutions brings flexibility, regeneration, and energy efficiency to End-of-Line testing for electric vehicles, batteries, and power electronics with a smart, cost-effective platform.